Envynn was born to combat the global plastic crisis. What began as a vision has transformed millions of PET bottles into valuable resources, redefining waste and sustainability through cutting-edge technology.

We create a closed-loop system that transforms waste into premium recycled products by converting used PET bottles into high-quality materials.

Empowering industries and individuals to adopt greener practices, fostering environmental responsibility at every level.

At Envynn Climatech Solutions, our cutting-edge manufacturing facility is at the heart of our commitment to sustainable recycling. With a focus on high efficiency and innovative practices, we transform plastic waste into valuable resources, achieving an impressive annual capacity of 13,860 tons.

At Envynn, our values fuel everything we do, guiding us to a cleaner, more sustainable world. We’re redefining recycling by focusing on impactful solutions, transparency, and collaboration. Each step we take is about building a better, greener future for all.

We champion eco-friendly practices that reduce waste and protect resources. Every action we take is a step toward a sustainable tomorrow.

Cutting-edge technology drives us forward. We continuously evolve, creating smarter, more efficient recycling solutions.

We unite with partners, communities, and clients, co-creating sustainable solutions that make a lasting impact.

Honest, ethical practices guide us. We earn trust through clear communication and steadfast accountability.

We deliver top-tier products that set new industry standards, ensuring excellence in every recycled piece.

We equip communities with the tools and knowledge to adopt sustainable practices and lead the change towards a better future.

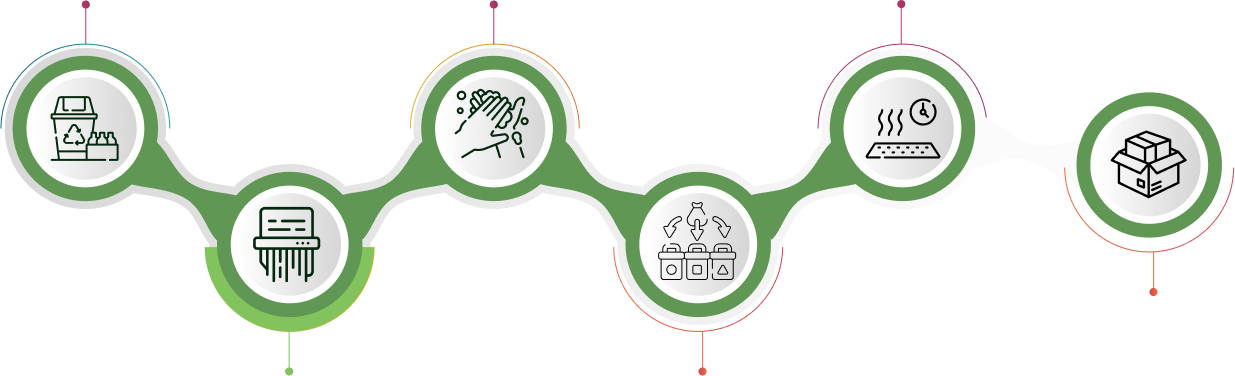

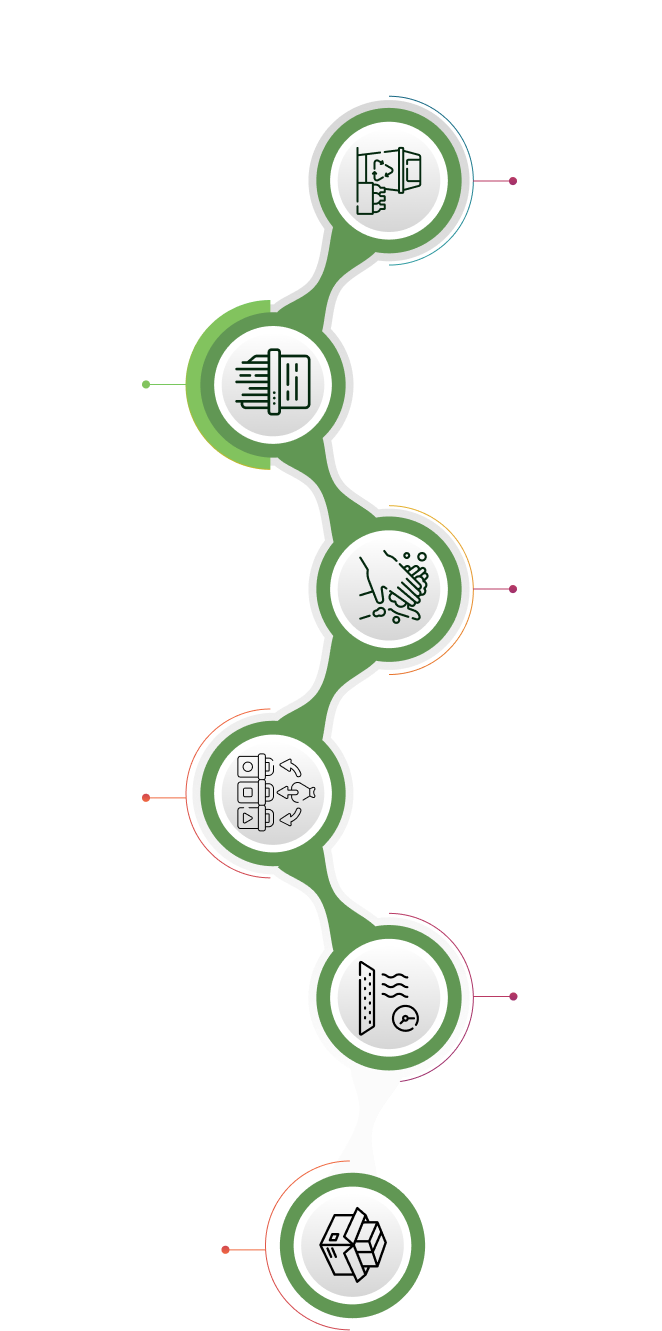

Every PET bottle has the potential to be reborn. Our advanced process transforms discarded bottles into premium PET flakes, ready for their next life in sustainable products.

Bottles gathered and sorted to remove impurities and non-PET plastics.

Float-sink methods isolate PET from contaminants with precision.

Moisture is eliminated with high-temperature drying, ensuring peak quality.

Each flake tested and packaged, meeting industry standards for purity and performance.

Bottles shredded into manageable flakes for further processing.

Flakes meticulously cleaned to remove labels, adhesives, and residues.

Every PET bottle has the potential to be reborn. Our advanced process transforms discarded bottles into premium PET flakes, ready for their next life in sustainable products.

Bottles gathered and sorted to remove impurities and non-PET plastics.

Bottles gathered and sorted to remove impurities and non-PET plastics.

Bottles gathered and sorted to remove impurities and non-PET plastics.

Bottles gathered and sorted to remove impurities and non-PET plastics.

Bottles gathered and sorted to remove impurities and non-PET plastics.

Bottles gathered and sorted to remove impurities and non-PET plastics.

Located 43 km from Kolkata Port and 133 km from Haldia Port for easy logistics

Water plays a key role in our PET flakes production. We prioritize efficient usage, recycling, and minimal waste to maintain sustainable operations.

Located 43 km from Kolkata Port and 133 km from Haldia Port for easy logistics

25,000 liters/day reused in operations.

Water will be sourced from a borewell and stored in a reservoir.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Full-service EPR solutions covering plastic waste, recycling graphics, and compliance for brands.

Full-service EPR solutions covering plastic waste, recycling graphics, and compliance for brands.

Creating a greener future while energizing local communities and economies—where sustainability meets progress.